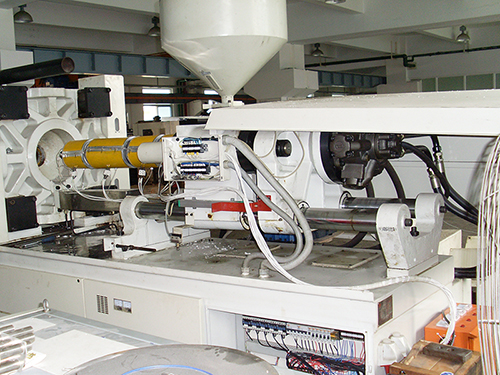

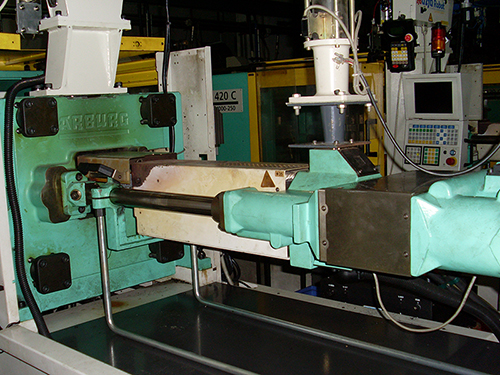

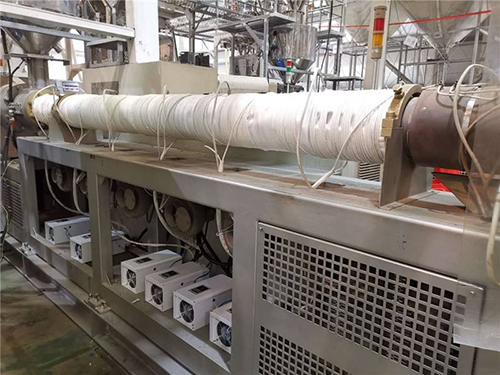

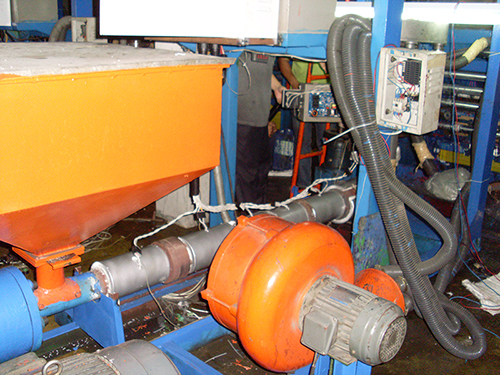

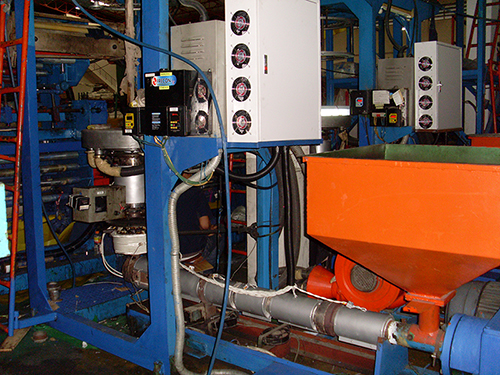

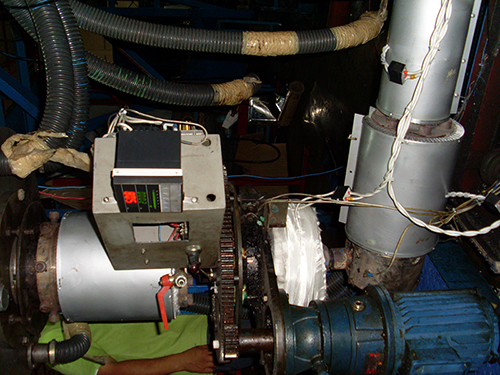

Induction Heating for Plastic Processing Machinery

This solution aims at using induction heating to replace resistance heating for plastic processing machinery. As a result, the energy efficiency, processing performance, productivity, control precision and operation stability of plastic machine are all improved.

Benefits of Induction Heating

- Energy efficiency 30%-85%

Currently, plastic processing machinery mainly uses resistance heating elements which can produce a large amount of heat radiated to the surroundings. Induction heating is an ideal alternative to solve this issue. The surface temperature of induction heating coil ranges between 50ºC and 90ºC, the heat losses are significantly minimized, providing energy savings of 30%-85%. The energy saving effect is therefore more obvious when the induction heating system is used in high power heating equipment. - Safety

Using induction heating system enables the surface of the machine to be safe for touching, and that means it can avoid burn injuries which often occur in plastic machines that use resistance heating elements, providing a safe workplace for operators. - Fast heating, high heating efficiency

Compared to resistance heating whose energy conversion efficiency is approximately at 60%, the induction heating is over 98% efficient at converting electricity to heat. - Lower workplace temperature, higher operation comfort

After using induction heating system, the temperature of entire production workshop is lowered by more than 5 degrees. - Long service life

In contrast to resistance heating elements that have to long-lasting work at high temperature, the induction heating works at near ambient temperature, therefore efficiently prolonging the service life. - Accurate temperature control, high product qualification rate

The induction heating provides low or no thermal inertia, so that it will not cause the temperature overshoot. And the temperature can remain at set value of 0.5 degree difference.

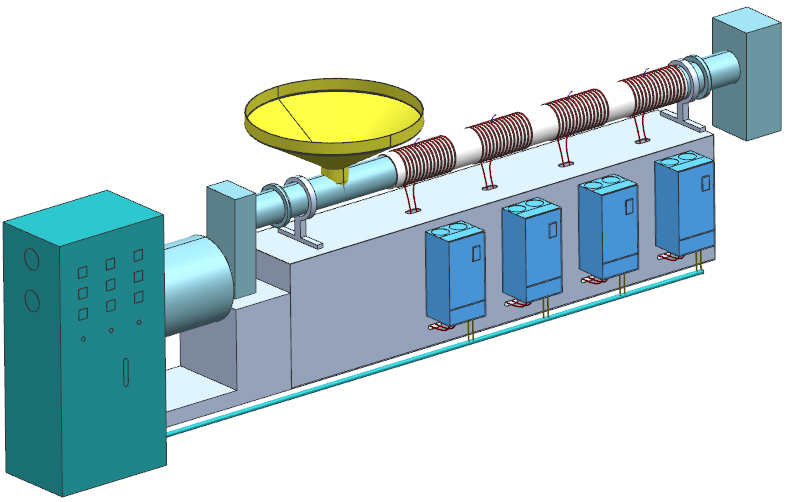

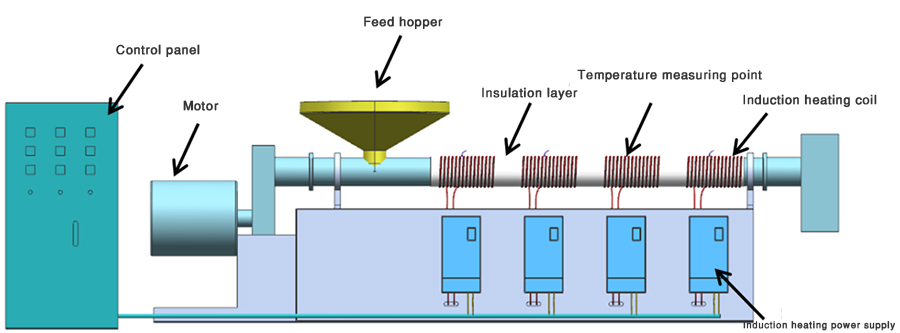

3D Modeling Diagram

Induction Heating Power Calculation

In the case of knowing the heating power of existing heating system, selecting an appropriate power according to load rate

- Load rate ≤ 60%, applicable power is 80% of the original power;

- Load rate between 60%-80%, select the original power;

- Load rate > 80%, applicable power is 120% of the original power;

When the heating power of existing heating system is unknown

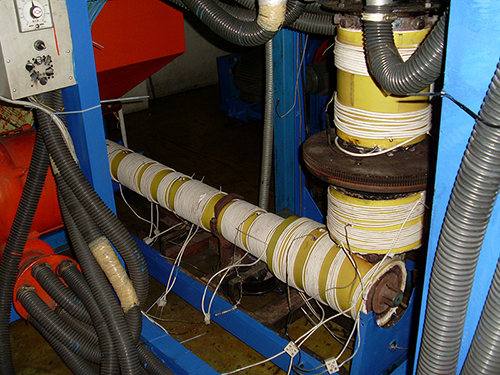

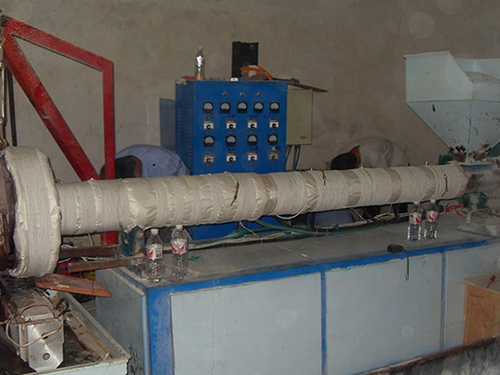

- For injection molding machine, blown film machine and extrusion machine, the power should be calculated as 3W per cm2 according to the actual surface area of the cylinder (barrel);

- For dry cut pelletizing machine, the power should be calculated as 4W per cm2 according to the actual surface area of the cylinder (barrel);

- For wet cut pelletizing machine, the power should be calculated as 8W per cm2 according to the actual surface area of the cylinder (barrel);

For example: cylinder diameter 160mm, length 1000mm (i.e. 160mm=16cm, 1000mm=100cm)

Cylinder surface area calculation: 16*3.14*100=5024cm²

Calculating as 3W per cm2: 5024*3=15072W, i.e. 15kW

Main Products

Request a Quote? Feel free to contact us at any time!

Click Here