Induction heating coils are produced in accordance with the size of drying drum, and placed inside the drum. When the rotary drum dryer is rotating, the induction heating coil remains stationary. The induction heating system runs to heat inner temperature of the drying drum.

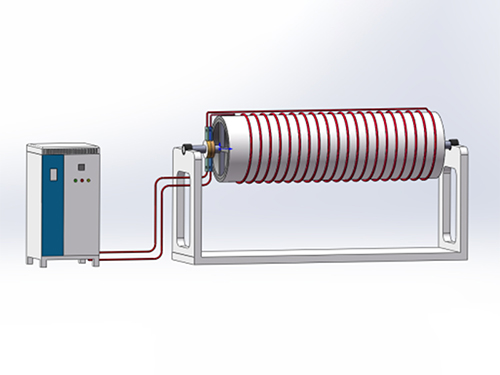

Induction Heating with Multi-Turn Helical Internal CoilInduction heating coils are wound inside the drying drum, the multi-turn helical wound coils and drying drum are rotated simultaneously. The induction heating system runs to heat inner temperature of the drying drum.

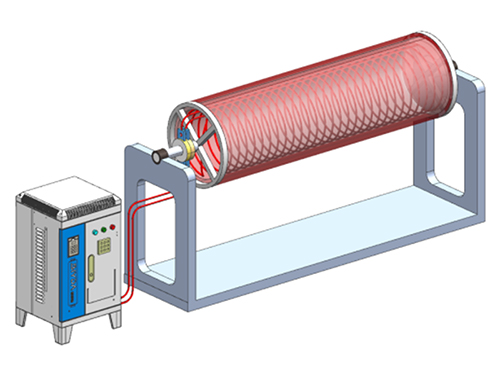

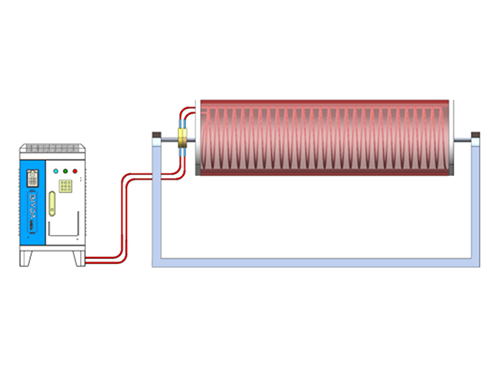

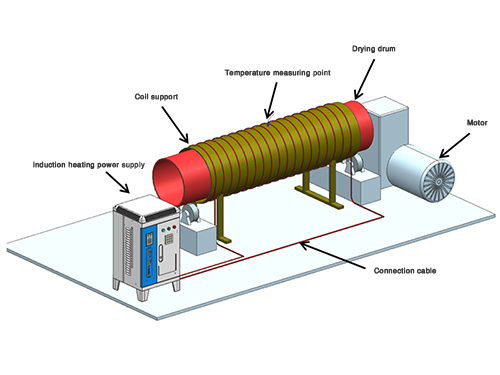

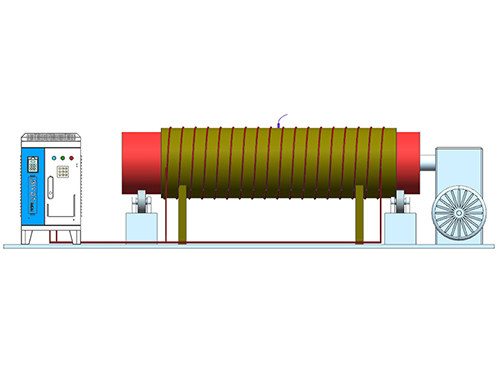

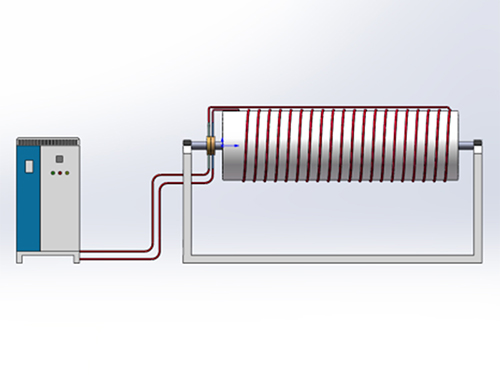

Induction Heating with Stationary Multi-Turn Helical External CoilInduction heating coils are wound closely around the support, and there is certain spacing between the coil support and drying drum. When the drying drum is rotating, the induction heating coil remains stationary. The induction heating system runs to heat the drying drum in a rapid and efficient manner.

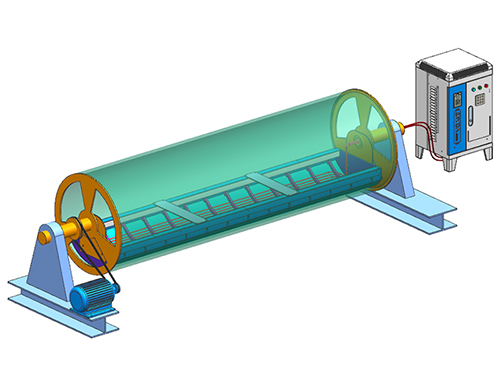

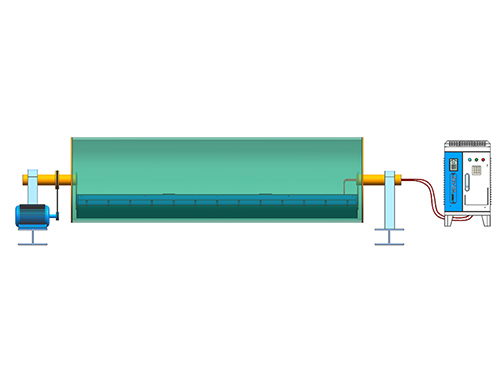

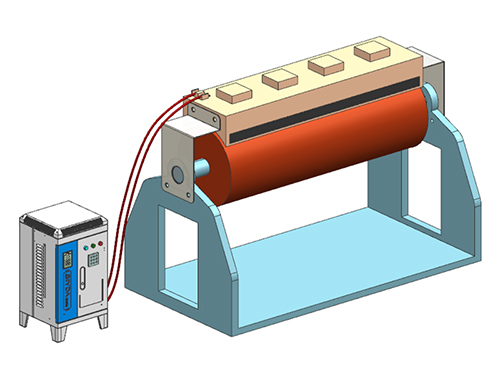

Induction Heating with Stationary External CoilInduction heating coils are curved external coils fixed on the support above the drying drum. When the drying drum is rotating, the induction heating coil remains stationary. The induction heating system runs to heat the drying drum in a rapid and efficient manner.

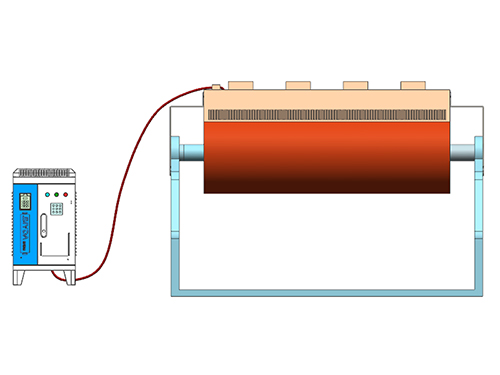

Induction Heating with Multi-Turn Helical External CoilInduction heating coils are wound around the insulation cotton which is wrapped around the drying drum. The multi-turn helical wound coils and drying drum are rotated simultaneously. The induction heating system runs to heat the drying drum in a rapid and efficient manner.