- One key start, steam is produced within 5 seconds without pre-heating

Compared to traditional resistance heating that takes 5 minutes to produce steam and traditional coal fired boiler that takes 50 minutes to produces steam, induction heating offers higher heating efficiency with only 5 seconds, greatly saving energy, time and cost. - Intelligent control, easy to operate

Intelligent control system, real-time display of steam temperature and pressure, 24-hour segment timer start / shut down, one-key start are significant features making operator to use. Besides, attended monitoring is not required, so that the labor cost is efficiently reduced. The system is certified in accordance with 3C Certificate and Special Furnace Body Qualification Certificate, the service life can reach 10-12 years. - Safety and reliability

The steam generator that adopts inducting heating technology has insulator between electric wire and heating unit, so it will not cause electricity leakage. Fault detection and alarm system provides comprehensive protection in all aspects of water leakage, electricity leakage, high pressure, high temperature, water shortage, etc. - Modular installation

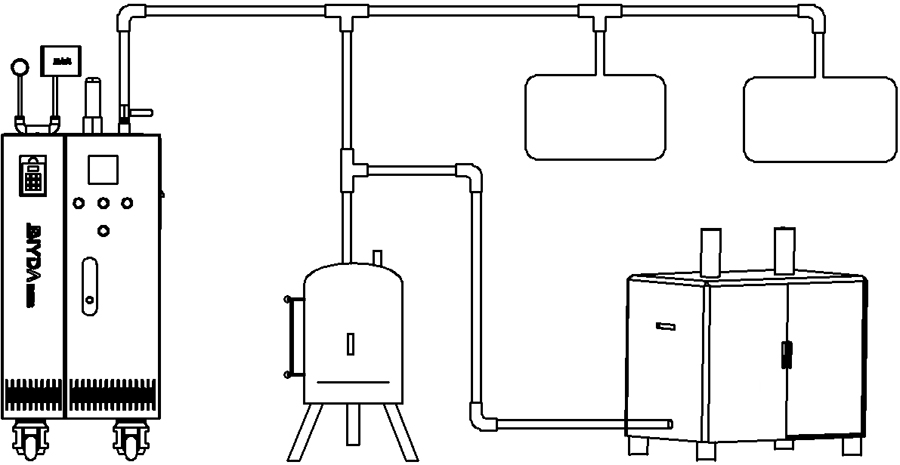

Induction heating steam generator can be installed individually, or multiple units in parallel to be used per actual application needs, thus providing easy installation and space saving while reducing installation expenses and piping cost. - No need for annual boiler inspection, highest steam temperature of 500ºC

Volume of heating unit is less than 30L, eliminating the need for annual boiler inspection. The pressure and temperature of the steam generator can be easily adjusted, allowing 500ºC high temperature steam to be produced under extreme low pressure. - Energy efficiency 30%-60%

Induction heating is over 98% efficient at converting electricity to heat, it saves more than 30% energy in comparison with traditional resistance heating method. The induction heating steam generator is 10-50 times faster than traditional boilers in steam production, it currently is an energy efficient steam generator in the market. - Eco-friendly, clean workplace

With no need for open flame, induction heating does not produce dust, odor, noise and hazardous gases, compliant with the requirements of National Energy Conservation Policy, and providing safer and cleaner workplace for operators. - Combining techniques of water cooling and waste heat recovery

With exclusive patent technology, the system features high waste heat utilization and efficient energy saving.

When selecting an induction heating steam generator, the required amount of steam needs to be determined. There are several calculation methods as follows:

- Using heat transfer formula to calculate the required amount of steam.

- Using flowmeter to directly measure the volume of steam.

- Using rated heating power provided by equipment manufacturer. In general, there is a standard rated heating power displayed on equipment nameplate, the unit “kW” stands for heat output and the unit “kg/h” stands for required steam consumption which will depend on the steam pressure.

To calculate the steam consumption according to applications:

-

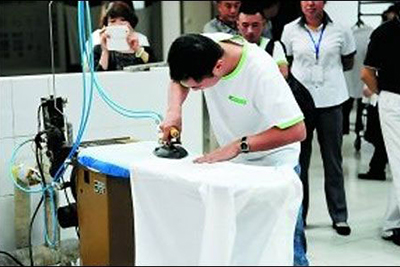

Laundry

In laundries, the selection of steam generator is mainly based on the equipment used, such as washing machine, dry cleaning machine, laundry dryer, ironing machine, etc. The steam consumption is generally indicated on the laundry equipment. -

Hotel

The selection of steam generator used in hotels is primarily based on estimating steam consumption according to the quantities of rooms, staffs, occupancy rate and laundry working hours. -

Factory and Workplaces

In factories and workplaces, users can refer the amount of steam used in their boilers which are previously used. For those new projects, users have to measure and calculate according the rating of the equipment provided by manufacturer.